How Are Plastics Used in the Manufacturing of Solar Panels?

Plastics play a significant role in the manufacturing process of solar panels, helping to reduce costs and improve efficiency.

Solar panels provide a sustainable and renewable energy source for businesses and homes. Plastic extrusion is used in producing solar panels, helping to create a lightweight and durable product that can withstand various weather conditions.

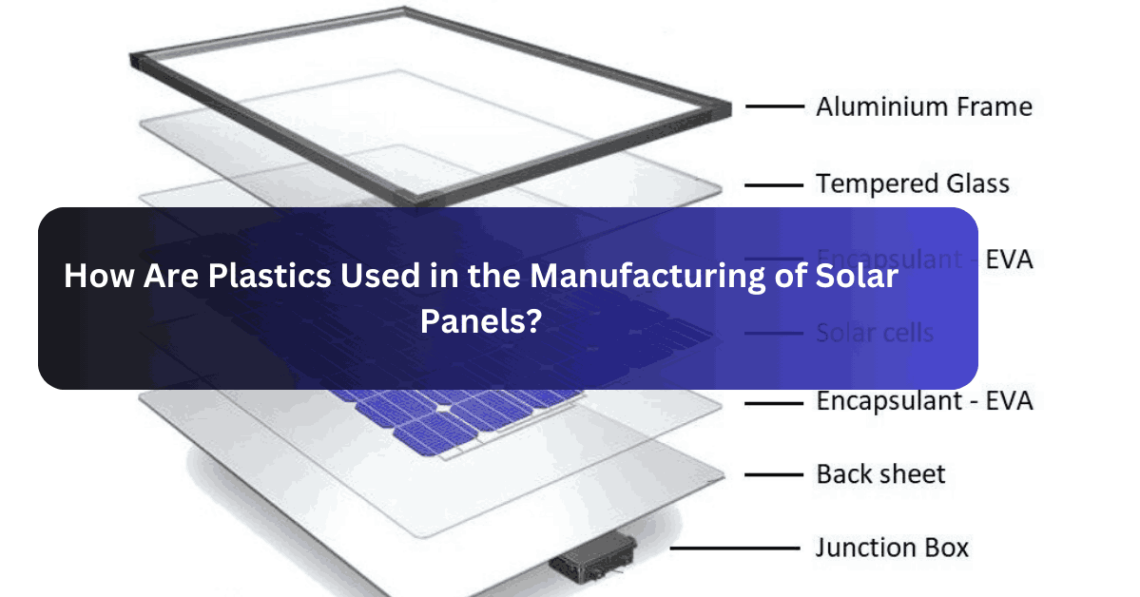

Here is an overview of how plastics are used in the manufacturing of solar panels:

Safeguarding the Cells

Solar panels comprise small, interconnected solar cells made from silicone. These cells convert sunlight into electricity and then harness it for various applications.

Plastics are used to safeguard these delicate solar cells during the manufacturing process. The plastic layers protect the solar cells from dust, moisture, and external damage that can affect their efficiency and durability.

The added protection provided by plastics helps solar panels generate electricity for a longer period, contributing to their cost-effectiveness and sustainability.

Directing Sunlight

Plastics direct sunlight onto the solar cells, increasing their exposure to sunlight and improving efficiency. Plastic films or lenses are placed on the solar panels, acting as a protective cover while allowing light to directly pass through and reach the solar cells.

These plastic components are designed with special coatings that prevent damage from UV rays, providing long-lasting performance of the solar panels.

Plastics are lightweight and easy to shape, making them ideal for solar panel designs requiring precise light reflection and concentration.

Insulating Properties

Solar cells are sensitive to temperature changes, and excess heat can reduce efficiency. Plastics are a barrier, preventing heat from escaping and maintaining a constant temperature inside the solar panel.

Ethylene-vinyl acetate (EVA) is placed between the solar cells and the back sheet, providing a cushioning layer that helps to absorb shocks and vibrations.

EVA also has low thermal conductivity, meaning it does not transfer heat easily, helping to maintain a stable temperature within the panel.

In solar panels, PU foam is often used as a backing layer behind the solar cells. They can provide additional insulation and help to maintain a constant temperature. Plastic extrusion creates frames for solar panels, providing structural support and a protective layer for the cells.

These plastic frames are designed to withstand harsh weather conditions and protect the delicate solar cells from damage.

Fitting for Outdoor Use

Plastics are highly durable and weather-resistant, making them suitable for outdoor solar panel installations. They can withstand extreme temperatures, moisture, and UV exposure without degrading or losing structural integrity.

This makes plastic components ideal for the longevity and performance of solar panels, especially in areas that experience harsh weather conditions. Plastics are non-corrosive, making them an ideal choice for long-term outdoor use.

Elevate Your Solar Panels with Plastic Extrusion

Solar panels offer a cost-efficient and sustainable way of generating electricity. Plastics play a role in manufacturing solar panels, providing structural support, insulation, and protection from harsh weather conditions.

Plastic extrusion technology helps produce frames for solar panels, making them more durable and corrosion-resistant. Join the green revolution and positively impact the environment with the help of extrusion technology in solar panel manufacturing

You May Also Like

The BMW S1000RR – A Complete Guide!

February 20, 2025

Installing Artificial Turf on Slopes and Uneven Terrain In 2023

November 15, 2023![Gramelle App V10.0 Download FREE | Free Instagram Followers and Likes [2022]](https://technomantu.net/wp-content/uploads/2022/07/Gramelle-App-V10.0-Download-FREE-Free-Instagram-Followers-and-Likes-2022.jpg)